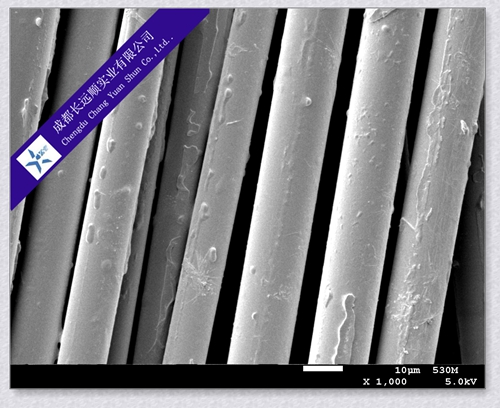

SMC Roving-326M

E glass SMC roving CYS-E326M is designed for high strength required products, coated with a high performance compound sizing compatible with unsaturated polyester resin, vinylester resin and so on. It's specially designed for the high strength performance SMC products, compare with other SMC roving CYS326M has better strength performace.

It is mainly used to produce automotive parts, doors, chairs, SMC water tanks and sports instruments etc.

|

Type of glass |

E |

|

Filament diameter (um) |

13 |

|

Linear density (Tex) |

2400, 4800 |

Product Feature:

1. Good choppability and good gathering.

2. Good dispersion and lay down.

3. Low static, excellent mechanical properties.

4. Excellent mold flowability & wet out.

Technical Parameters:

|

Linear density |

Filament diameter |

Moisture content |

LOI |

|

±5% |

13±1um |

≤0.10 |

1.20±0.15 |

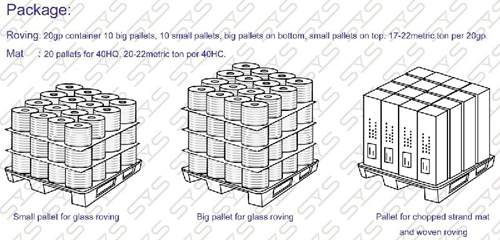

Packing:

The product can be packed on pallet in both small & big size pallet.

|

Bobbin height (mm) |

260 |

|

Bobbin inside diameter (mm) |

80 |

|

Bobbin outside diameter (mm) |

270 |

|

Bobbin weight (kg ) |

18-20 |

|

Number of layers |

3 |

4 |

|

Number of rolls per layer |

16 |

|

Number of rolls per pallet |

48 |

64 |

|

Net weight per pallet (kg) |

864-960 |

1152-1280 |

|

Pallet length (mm) |

1140 |

1140 |

|

Pallet width (mm) |

1140 |

1140 |

|

Pallet height (mm) |

955 |

1220 |

Download: E_Glass_Roving_for_SMC.pdf E_Glass_Roving_for_SMC.pdf

Storage:

Fiberglass roving should be stored in its original packing in a dry and cool place. Best conditions are at temperatures from 15 to 35℃ and humidity between 35 to 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layer, care should be taken to correctly and smoothly move the top pallet.

|