Direct Roving for Pultrusion (E313)

E313 E glass direct roving for pultrusion is coated with silane compatible with polyester, vinylester and epoxy etc. It’s also compatible with many kinds of resins. It is used in the FRP extrusion molding and many kinds of FRP materials, such as tabernacles, gratings, poles and cable slot.

|

Type of glass |

E |

|

Filament diameter (um) |

13, 17-24 |

|

Linear density (Tex) |

1200, 2400, 4800, 9600 |

Product Feature:

1. Good mechanical properties.

2. Complete & fast wet out in resins.

3. No fuzz, even linear density.

4. Uniform tension, good gathering.

Technical Parameters:

|

Linear density |

Filament diameter |

Moisture content |

LOI |

|

±5% |

±1um |

≤0.10 |

0.55±0.15 |

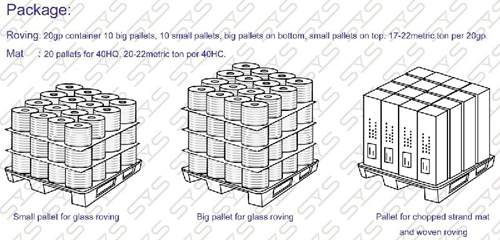

Packing:

The product can be packed on pallet in both small & big size pallet.

|

Bobbin height (mm) |

260 |

|

Bobbin inside diameter (mm) |

160 |

|

Bobbin outside diameter (mm) |

270 |

|

Bobbin weight (kg ) |

15-21 |

|

Number of layers |

3 |

4 |

|

Number of rolls per layer |

16 |

|

Number of rolls per pallet |

48 |

64 |

|

Net weight per pallet (kg) |

720-1008 |

960-1344 |

|

Pallet length (mm) |

1140 |

1140 |

|

Pallet width (mm) |

1140 |

1140 |

|

Pallet height (mm) |

955 |

1220 |

Data sheet:  Direct_Roving_for_Polyester_Pultrusion.pdf Direct_Roving_for_Polyester_Pultrusion.pdf

Storage:

Fiberglass roving should be stored in its original packing in a dry and cool place. Best conditions are at temperatures from 15 to 35℃ and humidity between 35 to 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layer, care should be taken to correctly and smoothly move the top pallet.

|