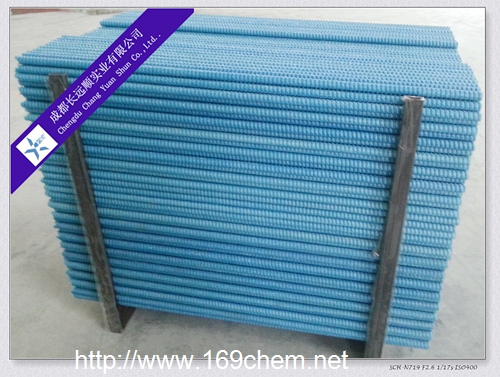

Fiberglass Rebar

Fiberglass Rebar (FRP rebar, GFRP rebar) is a highly structural fiberglass reinforcing bar made by process of pultrusion.

Fiberglass Rebar is used to reinforce concrete in applications where concrete is exposed to water, salt water, or chemical environments. Fiberglass rebar is the concrete reinforcement of reputable pre-cast concrete manufacturers for quality production.

Why chose fiberglass Rebar?

Fiberglass Rebar is an innovative product for reinforcing system where the following benefits are required:

1. Non-corroding, long service life

2. Non-magnetic: transparent to radio frequency

3. Light weight, Weight Reduction: 25% the weight of an equivalent size steel rebar

4. High mechanical strength: almost 200% tensile strength of an equivalent size steel rebar

5. Electrical Insulating: non-Conductive to electrical current

6. Thermal Insulating: non-Conductive to thermal transfer

7. Good heat resistant: Able to work in high temperature

8. Flame retardant & anti-static: no spark during cutting

9. Good machinability: Easy cut, punched, drilled

Where to use Fiberglass Rebar?

1. Magnetic equipment & radio frequency equipment

MRI facilities, Power transmission terminals, Micro-Tesla Calibration, Toll-Roads, airport tarmac, etc.

2. Mining and tunnel support

Fiberglass rebar can worked as structural support system of mining industry, metro, tunnel, side slope, etc. where requires weight reduction, no spark and easy operation.

3. Reinforcing concrete of harbor, waterway, coast

Fiberglass Rebar is impervious to attack by chloride ions (salt) and most common chemical agents.

4. Reinforcing concrete in construction

Fiberglass reinforcing bar combines concrete well. The inbuild color is designable. And the performance on corrosion resistance, light weight and easily cut also help fiberglass rebar become good material for constructions.

Which

|

Item |

Glass Fiber Reinforced Plastic |

|

Appearance |

screw thread / sand blasting |

|

Diameter(mm) |

From ø 3mm to ø 32mm |

|

Density(g/cm3) |

1.5—2.0 |

|

Tensile strength(MPa) |

≥550 |

|

Modulus of elasticity (GPa) |

30—41 |

|

Shape |

Most shapes available in steel are also available in fiberglass, although complicated bends, multiple plane shapes |

How is fiberglass rebar made?

A composite of highly corrosion resistant vinyl ester resin and glass fiber reinforcement formed into a rod shape, and coated with a coarse quartz sand to provide bond adhesion to concrete. |