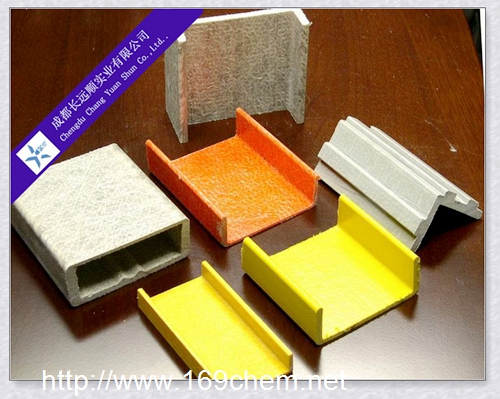

Structural Fiberglass FRP H-Beam

Fiberglass Reinforced I-Beam

Fiberglass Reinforced H Beam is a high-performance fiberglass beam manufactured through pultrusion process.

Unidirectional roving provides FRP H Beam longitudinal tensile strength, and continuous filament mat, woven roving, or stitched fabric provide the profile with its transverse properties.

Then, fiberglass reinforcement and resin impart FRP profiles excellent mechanical strength, electrical insulation, anti-corrosion etc.

Characteristics of Fiberglass Reinforced H I-Beam:

Non-corrosive

Lower life cycle cost

Easy to fabricate and install

Lightweight

High strength

High impact strength

Greater flexural strength than timber

Dimensional stablity

Electrically non-conductive and thermally non-conductive

Resists insect damage

Fire retardant

Wide working temperature

Low water absorption

Non-magnetic

Where to use Fiberglass Reinforced H-Beam?

1. Petroleum and Chemical Industry

The FRP H Beam characters good corrosion resistance property. It can be widely used in Petroleum and Chemical Industry as structural support of electricity and pneumatic transmission line, generator radiator, stairway and handrail, operating platform, walk way, fuel tank, switch panel, switch board room, drainage pipe and drainage system, berth recognition marks and underwater recognition marks, padding support in tower and filter board, drilling platforms etc.

2. Electrical & Electronics Industry:

As its excellent electric insulation property, FRP H Beam is widely used as insulation support profiles, insulation ladder, high voltage power supply operating board, etc.

3. Building Construction Industry:

Oversize bridge protection closed system, movable house structure, working platform, window frame, window sash and its components, etc.

4. Foundation Engineering Industry:

Freeway antiglare shield and its handrail, lamp post, water treatment, bracket foe huge industry cooling tower, etc.

5. Transportaion system:

Used as compression bar, corner board, acoustic absorption board and anti-glare panel, ect.

6. Cold storage: As it is non-conductive thermal insulation material, it can be used as framework material of freezer and cold storage.

Which specifications are available?

Fiberglass Reinforced H-Beam Pultrusions are available in three series for different applications and environments.

|

Standard Grade

|

General purpose structural grade. Isophthalic polyester resin system with good corrosion resistance.

Color: olive green. |

|

Fire Retardant

(FR)/UV Grade

|

General-purpose series utilizing fire-retardant isophthalic polyester resin system with a UV inhibitor. Color:

Gray or yellow |

|

Fire Retardant Vinylester

(VE Grade)

|

Fire retardant vinylester resin with fire retardance, low smoke generation and highly corrosion resistant.

Color: Sand Beige |

Note: Customer size, color and length are available.

How is fiberglass reinforced H-Beam made?

Pultrusion is a manufacturing process for producing continuous lengths of fiberglass reinforced plastics shapes with a constant cross section. All fiberglass reinforcements are first fed through preforming guides, then pulled through a bath of resin and through a heated die into its final shapes. The resin bath contains a mixture of resin, most commonly polyester or vinylester, pigments to add color and filler to enhance properties. After composite (FRP profile) coming out from the die, it allows post-cure during Pulling system and then cut into stock lengths.

|