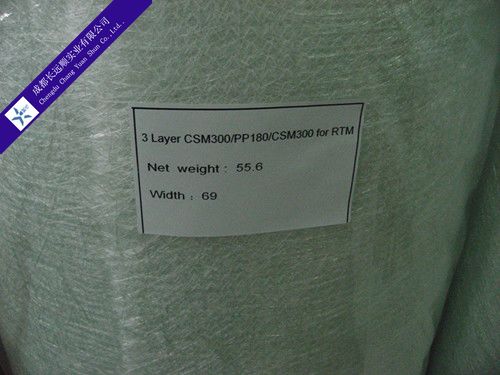

Chopped Core Mat-CCM300/P180/300

Identification:

Example: CCM300/P180/300

CCM: Chopped Core Mat

300: Nominal weight per square meter 300g/m2 of top mat.

P180: Nominal weight per square meter 180g/m2 of non-woven fabrics.

300: Nominal weight per square meter 300g/m2 of bottom mat.

Specification:

|

Construction |

Area weight |

Tolerance |

Remark |

|

Top mat |

300 |

±10 |

E glass fiber 2400tex |

|

Core |

180 |

±10 |

Non-woven fabric 180 |

|

Bottom mat |

300 |

±10 |

E glass fiber 2400tex |

|

Stitching |

14 |

±10 |

Polyester 167d’tex |

|

Total area weight |

794 |

±10 |

-- |

|

Stitch gauge: 3.5 gauge/25mm |

Stitch style: tricot stitch |

|

Stitch length: 4.5mm |

Loss on ignition: -- |

|

Moisture content: ≦0.2% |

Width: ±10mm |

|

Color tracer |

-- |

|

Specification |

Width (mm) |

Fiberglass roving

(g/m2) |

PP

(g/m2) |

Fiberglass roving

(g/m2) |

Weight

(g/m2) |

|

CYS300/180/300 |

250-2600 |

300 |

180 |

300 |

790 |

|

CYS450/180/450 |

250-2600 |

450 |

180 |

450 |

1090 |

|

CYS600/180/600 |

250-2600 |

600 |

180 |

600 |

1390 |

|

CYS300/250/300 |

250-2600 |

300 |

250 |

300 |

860 |

|

CYS450/250/450 |

250-2600 |

450 |

250 |

450 |

1160 |

|

CYS600/250/600 |

250-2600 |

600 |

250 |

600 |

1460 |

Packing:

Product is manufactured in form of a roll wound on a paper tube and then packed in a plastic film and placed within craft on pallet.

Above package is standard one, any other package style is negotiable by both of us.

Storage:

It is recommended that the fiber glass is stored in a cool and dry environment. Recommended temperature range of storage is between 10-30℃ and relative humidity between 50-75%. The fiber glass should store in the packaging until just prior to use.

Remark:

Other specification is available upon request. |