E Glass direct Roving for Thermoplastics

E glass direct roving for thermoplastics can be used for reinforcing PBT/PET,PA,

PEC, PP, and ABS, etc. Assembled roving is also available.

LFT process, LFT roving.

It is widely used in automotive parts, home appliances, machines tools, chemical corrosion

resistance and sports goods.

|

Type of glass |

E |

|

Filament diameter (μm) |

17 |

|

Linear Density (tex) |

2000 |

Product Feature:

1. Consistent fiber linear density.

2. Complete & fast wet-out in resins.

3. Good mold ability and dispersion.

4. Good mechanical properties of parts.

Technical Parameter:

|

Linear Density |

Filament diameter |

Moisture content |

LOI |

|

2000±1% |

±1 |

≤0.10 |

0.3±0.1 |

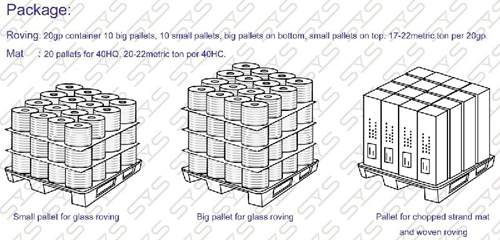

Packing:

The product can be packed on pallet in both small & big size pallet.

|

Bobbin height (mm) |

260 |

|

Bobbin inside diameter (mm) |

80 |

|

Bobbin outside diameter (mm) |

270 |

|

Bobbin weight (kg ) |

18-25 |

|

Number of layers |

3 |

4 |

|

Number of rolls per layer |

16 |

|

Number of rolls per pallet |

48 |

64 |

|

Net weight per pallet (kg) |

864-1200 |

1152-1600 |

|

Pallet length (mm) |

1140 |

1140 |

|

Pallet width (mm) |

1140 |

1140 |

|

Pallet height (mm) |

955 |

1220 |

Download:  E_Glass_PP_roving.pdf E_Glass_PP_roving.pdf  E3281_LFT.pdf E3281_LFT.pdf

Storage:

Fiberglass roving should be stored in its original packing in a dry and cool place. Best conditions are at temperatures from 15 to 35℃ and humidity between 35 to 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layer, care should be taken to correctly and smoothly move the top pallet.

|