Chopped Strand Mat for Hand Lay-up

CYS-E-CSMH Chopped Strand Mat for hand lay-up is produced by E-glass chopped strands around 50mm in length, bonded together by powder or emulsion binder which is extremely soluble in styrene.

The silane sizing system of basic strands and the nature of thebinder make E-CSMH suitable for use with epoxy, vinylester and UP resins in the following applications: automotive, trucks, sport and leisure, urban, industrial and marine parts, etc.

Product Features:

Excellent impregnation properties

Excellent conformability

Good mechanical properties

Good drapability

|

Type of Glass |

E |

|

Unit weight (g/m2) |

100~900 |

|

Width (cm) |

20~320 |

|

Binder |

Powder, Emulsion |

Technical Parameters:

|

Unit weight |

Width |

Moisture content |

LOI |

|

<10% |

±5mm |

≤0.2% |

2~4% |

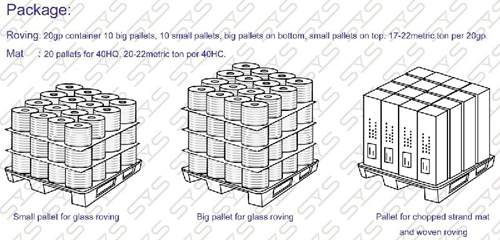

Packaging

Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 80mm. The roll outside diameter is approximately 275mm. Each roll is wrapped up in plastic film and then packed in a carton. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Carton size:

|

Package height(mm) |

Width+50 |

|

Package inside diameter (mm) |

80 |

|

Package outside diameter(mm) |

275 |

|

Package weight(kg) |

20.8kg-45kg |

Pallet size:

|

Palletlength (mm) |

1140 |

1400 |

|

Pallet width (mm) |

1140 |

1140 |

|

Pallet height (mm) |

Width+50 |

Width+50 |

Data sheet:  CSM.pdf CSM.pdf

Storage

Chopped strand mat should be stored in its original packaging in a dry, cool and water-proof place. The recommended conditions are at temperatures from 15 to 35°C and humidity between 35 and 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layer, care should be taken to correctly and smoothly move the top pallet.

|